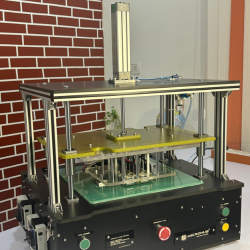

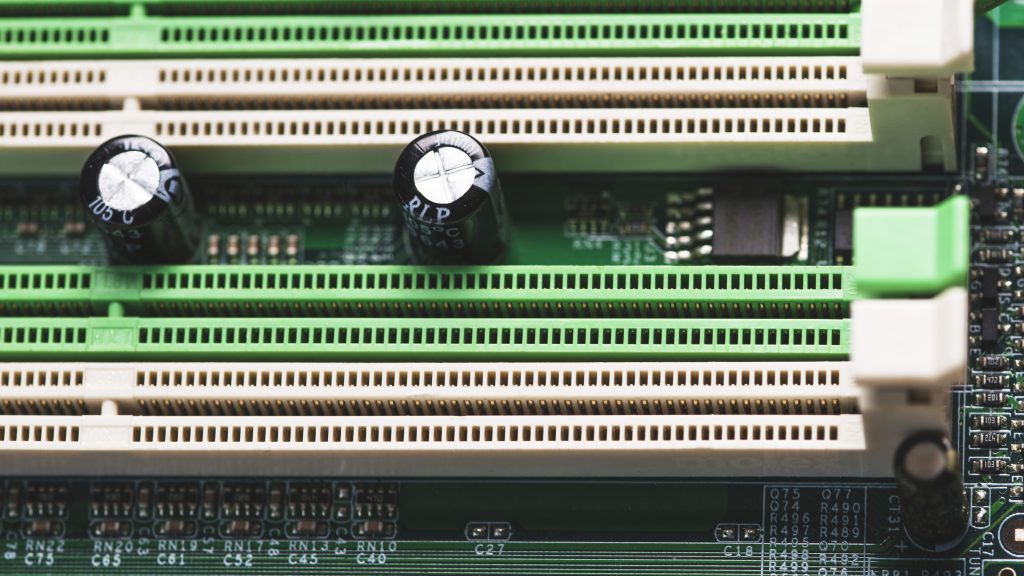

Microhub is focused on producing Functional Test Fixtures that meet the high demands of today’s electronics testing. Our fixtures help achieve the same good results in all industries, so product quality and performance are kept consistent.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

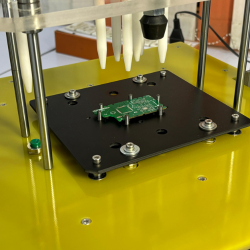

Fixtures allow for changes in the DUT design, ensuring that the parts are well aligned and make contact during testing.

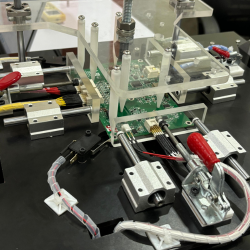

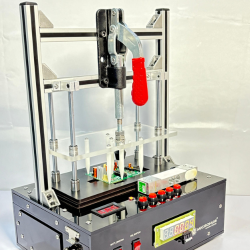

Manufactured using high-quality metals such as aluminum, stainless steel and Delrin to ensure frequent use does not break the instrument.

The guide pins, alignment blocks and clamps on the Produnant P21 make sure the DUT is always in place correctly.

Technicians will work with more comfort, meaning they can handle workloads faster and feel less tired.

You can quickly update the fixture for other types of DUTs or new testing requirements.

Allows for Product Functional Testing without the need for costly automation.

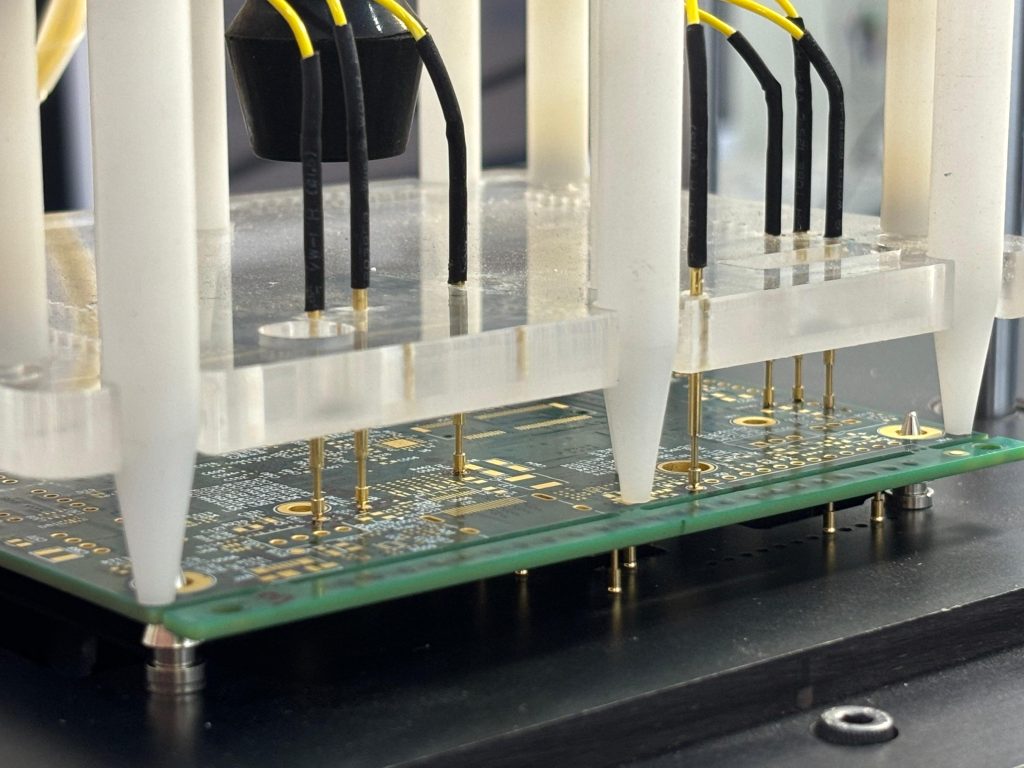

The test setup includes all the essential parts—guide pins, clamps and spring-loaded probes—for matching the DUT setup.

Using alignment instruments, technician places the DUT in the exact location needed for all tests.

The operator turns the fixture on to place test probes against the DUT’s test points.

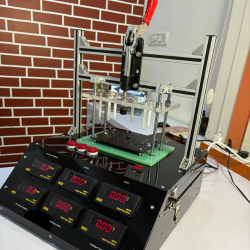

Here all the parameters user can see over panel mount meters and can connect required other device like DSO, Functional generator etch with fixture easily.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Ensure right alignment and connection between your PCB and testing equipment, resulting in accurate and reliable test results.

With ergonomic handles and levers, you can test products efficiently by hand.

Reliable connection between DUT pads and terminals is achieved with durable pogo pins.

Our onboard meters help in voltage testing, current testing, continuity testing, resistance testing, frequency testing, PWM testing, communication testing , Load/No load testing etc.

Our variety of flexible components is suited to meet many custom functional test fixture demands.

Robust machining and design methods keep the DUT properly aligned and make the mechanism more reliable.

Reliable connection between DUT pads and terminals is achieved with durable pogo pins.

Our variety of flexible components is suited to meet many custom functional test fixture demands.

With ergonomic handles and levers, you can test products efficiently by hand.

Our onboard meters help in voltage testing, current testing, continuity testing, resistance testing, frequency testing, PWM testing, communication testing , Load/No load testing etc.

Robust machining and design methods keep the DUT properly aligned and make the mechanism more reliable.

Reliable connection between DUT pads and terminals is achieved with durable pogo pins.

Our variety of flexible components is suited to meet many custom functional test fixture demands.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Microhub is known for creating high-quality solutions, using new ideas and serving clients well. After years in this industry, we make Functional Test Fixtures that are precise, easy to operate and tough.

We combine efforts with customers to tailor product functional testing solutions in line with their objectives. All of our fixtures are crafted carefully and checked against tough standards. Because we are constantly seeking new ways to improve, our testing solutions are always more dependable than anticipated.

With these fixtures, it is simple, fast and safe to set up and use each device, with all probes being properly lined up every time. Because of this, operators can do many tests more quickly, without the usual errors and it’s all much simpler than setting up previous equipment.

As a result, faster production, greater testing accuracy and less expense for labor are achieved. Because Microhub equipment is comfortable and reliable, teams can finish their testing faster and with less disruption.

WhatsApp us