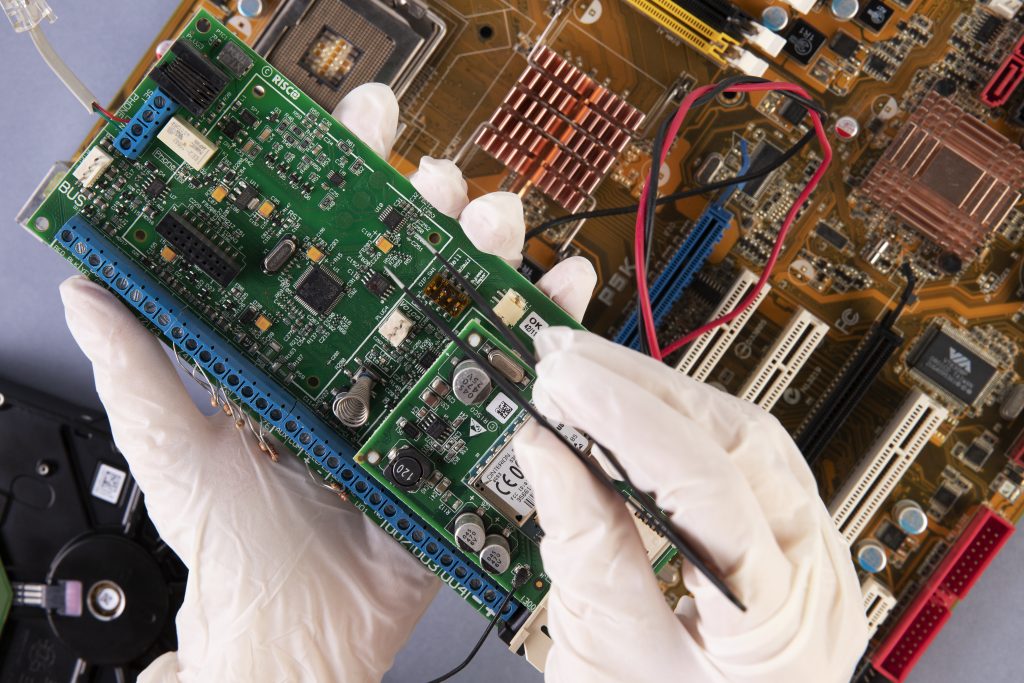

Microhub creates next-generation equipment for efficiently uploading firmware and programming devices. With our solutions, manufacturers are able to quickly and successfully apply firmware to many types of electronic products, allowing for dependable assembly lines and proper functioning of the goods.

Suited to your DUTs’ layout and connectors, this ensures the flashing process is reliable.

As they are made from strong materials, they survive many times of being used, repeating the flashing cycle without wear.

Uses alignment pins, probe blocks and clamping tools to aim at the flashing interface, regardless if it’s a header, pad or pogo pin array.

Intuitive and efficient features make flashing easy and fast, so technicians can complete many tasks before getting tired.

Different modules can connect different devices, making it simple to adapt to various PCB flashing test conditions.

This device is compatible with flashing machines or it can be flashed manually.

Place the probes and adjust the alignment devices to match how the firmware interface looks in the DUT.

Set the device in position by using both the guide pins and the hold-down clamps to make sure the probe is properly in contact.

Running the firmware software allows you to turn on flashing either manually or automatically.

When the firmware has been loaded, the system checks the result of the upload. After that, the DUT is removed for the purpose of validation or for deployment.

With machined components, fixtures guarantee accurate and dependable connections every usage.

Spring-loaded features guide the tip of a test probe to secure and stable contact with test points or connectors.

Works with both standard and custom flashing tools like USB, JTAG, UART and SWD interfaces.

Lever, handle and clamp mechanisms are designed to be easy to control and used for a long time.

With machined components, fixtures guarantee accurate and dependable connections every usage.

Spring-loaded features guide the tip of a test probe to secure and stable contact with test points or connectors.

Works with both standard and custom flashing tools like USB, JTAG, UART and SWD interfaces.

Lever, handle and clamp mechanisms are designed to be easy to control and used for a long time.

Robust machining and design methods keep the DUT properly aligned and make the mechanism more reliable.

Reliable connection between DUT pads and terminals is achieved with durable pogo pins.

Our variety of flexible components is suited to meet many custom functional test fixture demands.

With ergonomic handles and levers, you can test products efficiently by hand.

Our onboard meters help in voltage testing, current testing, continuity testing, resistance testing, frequency testing, PWM testing, communication testing , Load/No load testing etc.

Robust machining and design methods keep the DUT properly aligned and make the mechanism more reliable.

Reliable connection between DUT pads and terminals is achieved with durable pogo pins.

Our variety of flexible components is suited to meet many custom functional test fixture demands.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

WhatsApp us