Functional test fixtures are used to evaluate printed circuit boards (PCBs) under real or specified operating conditions. This test is done to see how the PCB performs under simulated workloads, helps reduce production errors, and ensures quality assembly.

In PCB assembly, functional testing is a critical measure of quality, and functional test fixtures are widely used to validate performance. Here’s a glimpse into the world of printed circuit board assembly (PCBA) and the specialized tool used to detect early-life failures.

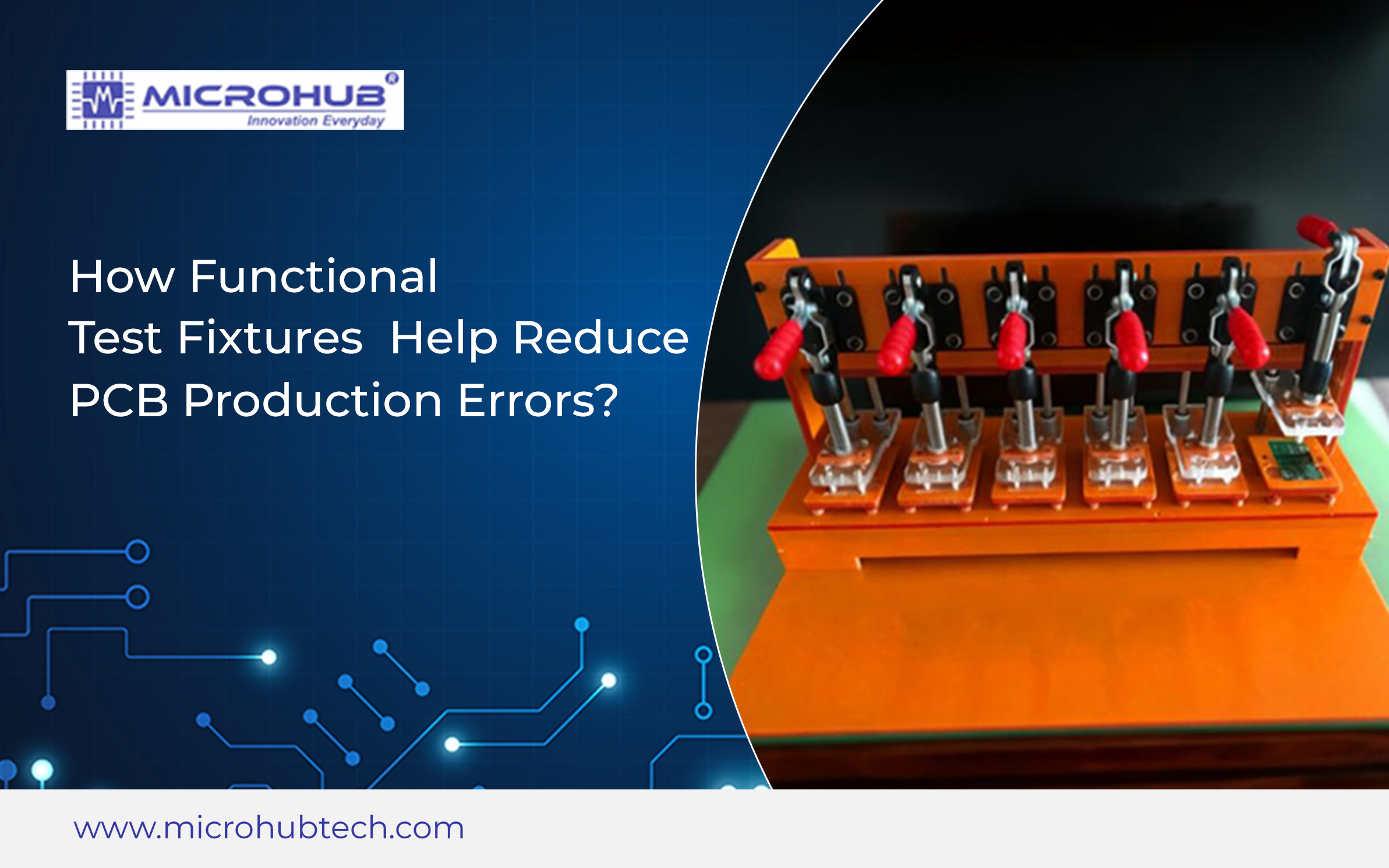

Functional Test Fixtures Used in PCB Production

While other PCBA test fixtures are suitable for applications requiring defect detection and high-accuracy measurements, a functional test fixture puts the PCB into real-world operating conditions to assess whether it will perform as expected.

Functional test fixtures are designed for speed, automation, and traceability. When combined with other fixtures, such as in-circuit test fixtures, they streamline the workflow from quality checks to final PCB assembly validation.

These systems deliver measurable value across a PCB’s lifecycle:

Production and Assembly

To ensure the PCB is defect-free before shipping, a manufacturer will conduct a full inspection test to verify the configuration post-PCB assembly. This test reduces the rates of out-of-box failures and improves brand reputation.

Service and Repair

For technicians, a functional test is the best way to distinguish between hardware and software issues. This systems detect configuration changes and validates reconfigurations before the PCB is returned to the user.

End-of-Life

Electronic testing fixtures assess PCB condition to confirm whether the board is functional, repairable, or dead by testing all hardware components. It standardizes testing for efficiency while identifying components that can be redeployed.

How PCBs Move from Concept to Customer?

Testing PCBs is crucial because it minimizes customer inconveniences. Functional test fixtures are integrated into the production process and assembly workflow to detect errors early and reduce product variability.

While it is possible to visually identify problems such as missing components, misalignment, soldering issues, and cold joints, the benefits of automation and using test fixtures include efficiency and consistency.

To perform the test:

- The PCB is placed inside a cavity designed for the configuration of the PCB.

- Pogo pins connect the PCB to power, sensors, and I/O ports.

- A test program runs simulations automatically.

- Data is collected and checked against a benchmark.

- Results are recorded as “pass” or “fail”.

Functional testing enables the PCB manufacturer to integrate additional quality control checks, ensuring comprehensive coverage. Additionally, the automation capabilities deliver higher accuracy and consistency.

There’s also the added advantage of automatically capturing test data into a repository that will prevent failure by optimizing the assembly process. This data helps improve the effectiveness of PCB assembly and keep processes within acceptable parameters.

The test fixture enhances precision by minimizing the need for human involvement. That way, it provides a consistent diagnostic benchmark that is applied to every PCB, leading to more reliable data for decision-making.

Why Functional Test Fixtures are More Reliable?

- Realistic Conditions: Electronic testing fixtures run a predetermined set of instructions that simulate the actual application environment. That means the result better reflects the functioning, performance, and stability of PCB components in normal operating conditions.

- Customization: Functional testing fixtures can be customized to the specific needs of every PCB assembly. It can accommodate unusual shapes, mimic user interactions, and tailor the test procedures for accurate results.

- Data Collection: All modern PCBA test fixtures collect large amounts of important and beneficial data that guide improvements in design and production. However, only data from functional tests can track recurrent issues through the PCB’s entire life cycle.

The Bottom Line

Functional test fixtures are high-accuracy, high-speed specialized tools used to identify issues that can lead to poor PCB performance or malfunctions. They allow manufacturers to focus on innovation and growth, knowing their products can meet the user’s needs.

At Microhub, we specialize in designing and manufacturing high-precision functional test fixtures that ensure every PCB leaving the production line meets the highest standards of reliability. Get custom solutions today!