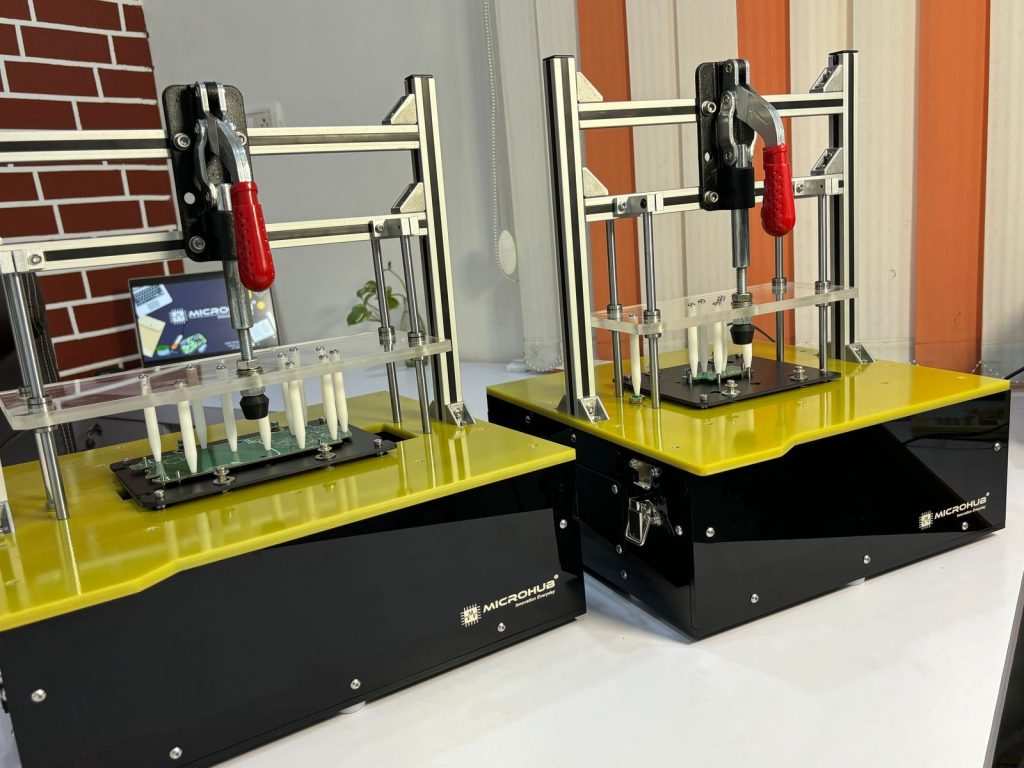

At Microhub, we specialize in creating and manufacturing high-precision manual test fixtures for today’s strict electronics testing needs. We design our fixtures to ensure that testing them gives repeatable and dependable results for different industries, so the products we test are always of high quality.

Many industries depend on manual test fixture to check quality, perform functional testing, and validate products. The fixtures safely lock and link DUTs to the tester for reliable and precise checking. With these testers controlled by hand, technicians can place and remove test boards, insert probes, and run tests by themselves.

Designed to suit different DUT shapes and sizes for the best contact and arrangement during testing.

Designed using aluminum, stainless steel, Bakelite, FR4 ESD safe, and Delrin, so the parts can take repeated use without becoming damaged.

With guide pins, alignment plates and clamping mechanisms, it guarantees the DUT is placed in an exact position.

Ready for easy operation by the workers, the devices help prevent operator fatigue and enhance the speed of testing.

The system includes interchangeable parts that adjust fast to different situations and devices.

It gives us a solid way to test without needing to buy expensive automatic systems.

The test fixture has the necessary equipment and alignment tools to suit the DUT. You should use guide pins, clamps and test probes as and when needed.

The DUT is positioned over the guide pins and into the holder to ensure that testing is done accurately.

The operator operates the fixture, causing its mechanism to connect the test probes to the DUT so that testing can start.

The appropriate tests start once the DUT and probes have been sorted out. As soon as the DUT is removed, the results are analyzed to assess performance and determine whether any issues are present.

Utilization of high-quality materials and machining processes to ensure durability and accurate alignment in fixture components.

Incorporation of reliable pogo pins to establish consistent electrical contact with DUT test points during testing.

Implementation of interchangeable modules to allow quick reconfiguration for different DUTs and manual PCB testing requirements.

Design of user-friendly levers and handles to facilitate easy operation and reduce operator fatigue during repetitive testing tasks.

Utilization of high-quality materials and machining processes to ensure durability and accurate alignment in fixture components.

Incorporation of reliable pogo pins to establish consistent electrical contact with DUT test points during testing.

Implementation of interchangeable modules to allow quick reconfiguration for different DUTs and manual PCB testing requirements.

Design of user-friendly levers and handles to facilitate easy operation and reduce operator fatigue during repetitive testing tasks.

Robust machining and design methods keep the DUT properly aligned and make the mechanism more reliable.

Reliable connection between DUT pads and terminals is achieved with durable pogo pins.

Our variety of flexible components is suited to meet many custom functional test fixture demands.

With ergonomic handles and levers, you can test products efficiently by hand.

Our onboard meters help in voltage testing, current testing, continuity testing, resistance testing, frequency testing, PWM testing, communication testing , Load/No load testing etc.

Robust machining and design methods keep the DUT properly aligned and make the mechanism more reliable.

Reliable connection between DUT pads and terminals is achieved with durable pogo pins.

Our variety of flexible components is suited to meet many custom functional test fixture demands.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

WhatsApp us